DC sliding gate openers are essential for automated access control in residential, commercial, and industrial environments. They offer both convenience and security. However, like all mechanical and electrical devices, they may develop operational issues over time. These issues often stem from improper use, component wear, or electrical faults. This article focuses on the most common problems with DC sliding gate openers. It also provides step-by-step troubleshooting solutions based on official instructional guidelines.

1. The DC Sliding Gate Openers Fail to Work

A non-functional opener is one of the most prevalent issues. It usually comes from power supply or wiring problems that disrupt the device’s basic operation.

Possible Reasons

- The opener system gets no power.

- The opener’s internal fuse blows, often due to electrical overload or short circuits.

- Wiring connections between the power source, control board, and other key components are faulty (e.g., loose, disconnected, or damaged wires).

Troubleshooting Steps –Sliding Gate Openers

- First, verify the main power supply. Ensure the opener’s power cord connects to a functional AC source (e.g., 110V/220V, regional-dependent). Confirm the outlet works with another device—this checks the initial input, which the opener’s built-in transformer converts to 24VDC.

- Confirm the transformer output. If main power is normal, use a multimeter to test the transformer. Ensure it outputs the required 24VDC (vital for the motor and control board). Replace the transformer if it has no output.

- If the power supply is normal, inspect the fuse. Replace it with a new fuse of the correct rating if it is blown.

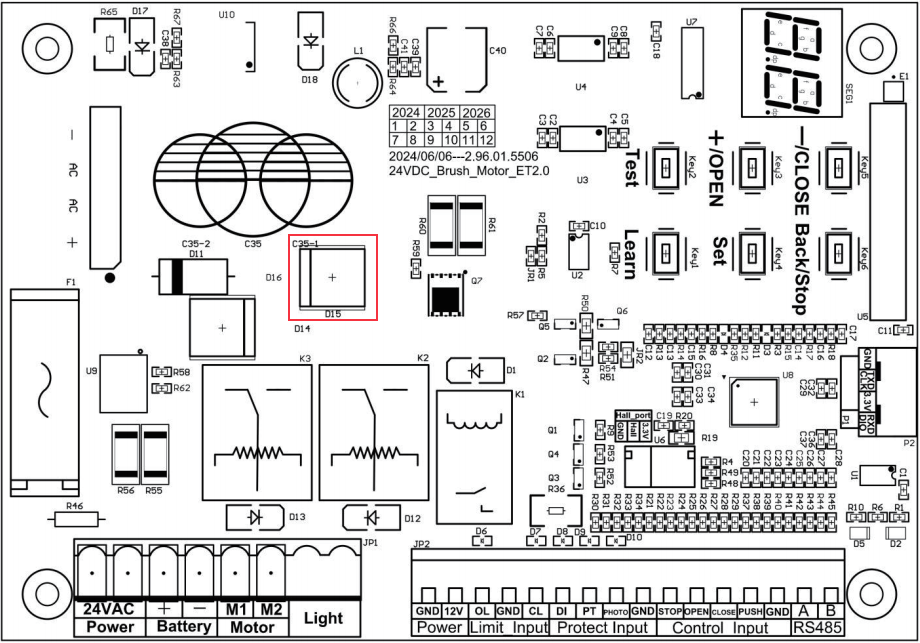

- Finally, cross-check all wiring connections against the opener’s wiring diagram. Reconnect any loose wires and replace damaged ones to restore stable electrical transmission.

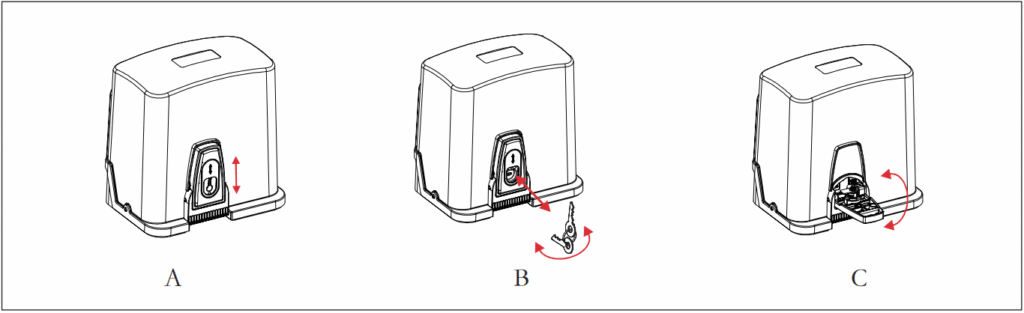

2. The Sliding gate Opener Runs, But the Gate Does Not Move

In this case, the opener may make operating sounds, but the gate stays still. This issue usually ties to the release clutch.

Possible Reason

The opener’s release clutch is in the unlocked position. The release clutch is designed for manual gate operation when power is off. But if it stays unlocked when power is on, the opener cannot drive the gate’s movement.

Troubleshooting Step

Use the dedicated release key to check and lock the clutch. Insert the key into the clutch mechanism and turn it clockwise (follow the manual’s instructions) until the clutch is securely coupled. Test the opener again to confirm the gate moves.

3. The Opener Stops 2 Seconds After Opening or Reverses 2 Seconds After Closing

This problem interrupts the gate’s normal cycle. It often comes from obstacles or incorrect parameter settings.

Possible Reasons

- An obstacle (e.g., debris, rocks) blocks the gate’s path, or the gate exceeds the opener’s maximum weight capacity (300Kg to 500Kg, depending on the model).

- The “reverse sensitivity parameter (C0)” on the control board is set too low. This triggers unnecessary reverse or stop responses.

Troubleshooting Steps

- Clear any obstacles in the gate’s travel path. Confirm the gate’s weight does not exceed the opener’s maximum capacity.

- If the issue persists, adjust the reverse sensitivity parameter (C0). Power on the opener and press and hold the “SET” button for 3 seconds to enter parameter-setting mode. Use the “OPEN” or “CLOSE” button to switch to parameter C0. Then press “OPEN” to increase the value (range: 0-20) and reduce sensitivity. Press “SET” to save the setting and “STOP” to exit.

4. The Gate Reverses When Closing

Gate reversal during closing is a safety-related issue. It often links to obstacles or faulty safety devices.

Possible Reasons

- An obstacle (e.g., small objects, overgrown plants) is in the gate’s closing path.

- Optional photocells (safety devices for obstacle detection) are not triggered correctly or are damaged. Photocells are critical to prevent the gate from closing on objects or people.

Troubleshooting Steps

- Thoroughly inspect the gate’s closing path and remove any obstacles.

- Check the photocells. Ensure they are properly installed, aligned, and free from dirt or damage. Clean the photocell lenses with a soft cloth if needed. Replace damaged photocells with compatible models as the manual recommends.

5. The Sliding Gate Opener Continues Running After the Gate Reaches the Limit Position

This issue risks component damage, as the opener fails to stop when the gate hits its open or close limits.

Possible Reasons

- The magnetic limit sensors (installed on the steel rack to define limits) are broken.

- The limit magnets are not installed in the correct positions on the rack.

- The polarity of the limit magnets is incorrect. This prevents the opener from detecting limit signals.

Troubleshooting Steps – Sliding Gate Openers

- Inspect the magnetic limit sensors and replace them if broken.

- If the sensors are intact, reinstall the limit magnets. Use the key to release the clutch, manually move the gate to the open and close limit positions. Mark these points on the rack and fasten the limit magnets at the marked positions.

- If the problem persists, flip the limit magnets to adjust their polarity and test the opener again.

6. The Fuse Blows Again Immediately After Replacement

Repeated fuse blowing means an underlying electrical fault exists. This requires urgent resolution.

Possible Reason

A high-voltage input is fed into the 12V power port of the control board, damaging components like the D15 diode or MOSFET and causing the fuse to blow repeatedly.

Troubleshooting Steps – Sliding Gate Openers

- Turn off the power supply. Then replace the damaged D15 diode and MOSFET with parts of the same specifications. Refer to the opener’s technical diagram for details.

- Recheck the power input connections. Ensure the 12V power port only connects to a 12VDC power source. Follow the opener’s wiring diagram to avoid incorrect connections.

Conclusion

Most common issues with DC sliding gate openers can be resolved through systematic troubleshooting based on official guidelines. To ensure safety and prevent further damage, always disconnect power before performing maintenance. Avoid modifying the opener’s components. Seek professional assistance if you are unsure about any steps. Regular inspections of power connections, safety devices, and limit components will also help maintain the opener’s performance and extend its lifespan.