Walk up to most sliding gates today, and you will see small blocks—either magnets or metal brackets—mounted on the gear rack. These are the physical markers that tell the gate where to stop.

But occasionally, you might encounter a sleek installation with absolutely nothing on the rack. The gate stops perfectly, yet there are no visible switches.

This is the realm of Encoder-Only Limits, sometimes called “Virtual Positioning.” It was once hailed as the future of gate automation. Yet, in 2026, it remains a niche solution, largely overshadowed by Hybrid Systems (Hall + Magnetic).

Why did this promising technology become a rarity? And how does it actually work?

1. The Mechanics: How “Virtual Limits” Work

Unlike mechanical switches that rely on physical contact, or magnetic switches that rely on proximity, an Encoder Limit system relies entirely on mathematical calculation.

The Hardware: The Encoder

Deep inside the motor housing, attached to the rear shaft, is a high-resolution sensor called a Rotary Encoder (typically optical or magnetic). As the motor spins, this encoder generates thousands of precise digital pulses per revolution.

The Process: The “Learning Run”

Before the gate can be used, it must perform a mandatory “learning run.”

- The gate moves slowly from fully closed to fully open until it physically hits a hard stop.

- The control board counts the total pulses for this journey. (e.g., “A full opening is exactly 48,500 pulses”).

- The software then sets “virtual limits.” It might decide that “Open Limit” is at 48,000 pulses and “Close Limit” is at 500 pulses, leaving a small safety margin.

From then on, the gate isn’t looking for a switch; it’s simply counting down from 48,500 to zero every time it moves.

(See Image 1 below for a visualization of the internal encoder.)

2. The Allure: Why use Encoders? (The Pros)

Encoder systems offer distinct advantages that still appeal to specific segments of the market:

- Aesthetic Cleanliness: For high-end residential architects, the absence of ugly magnets or brackets on the gate rack is a significant visual plus.

- Installation Simplicity (Initial): Installers don’t need to crouch down and painstakingly adjust the gap between a magnet and a sensor. It’s “bolt-on and learn.”

- Software Precision: Want the gate to open only 30% for pedestrians? With an encoder, this is a simple software setting (e.g., “Stop at 14,550 pulses”). With physical switches, this is nearly impossible.

(See Image 2 below for a diagram of the pulse-counting principle.)

3. The Decline: Why are they rare today? (The Cons)

If they are so precise and clean, why aren’t they the industry standard in 2026? The answer lies in long-term reliability versus environmental reality.

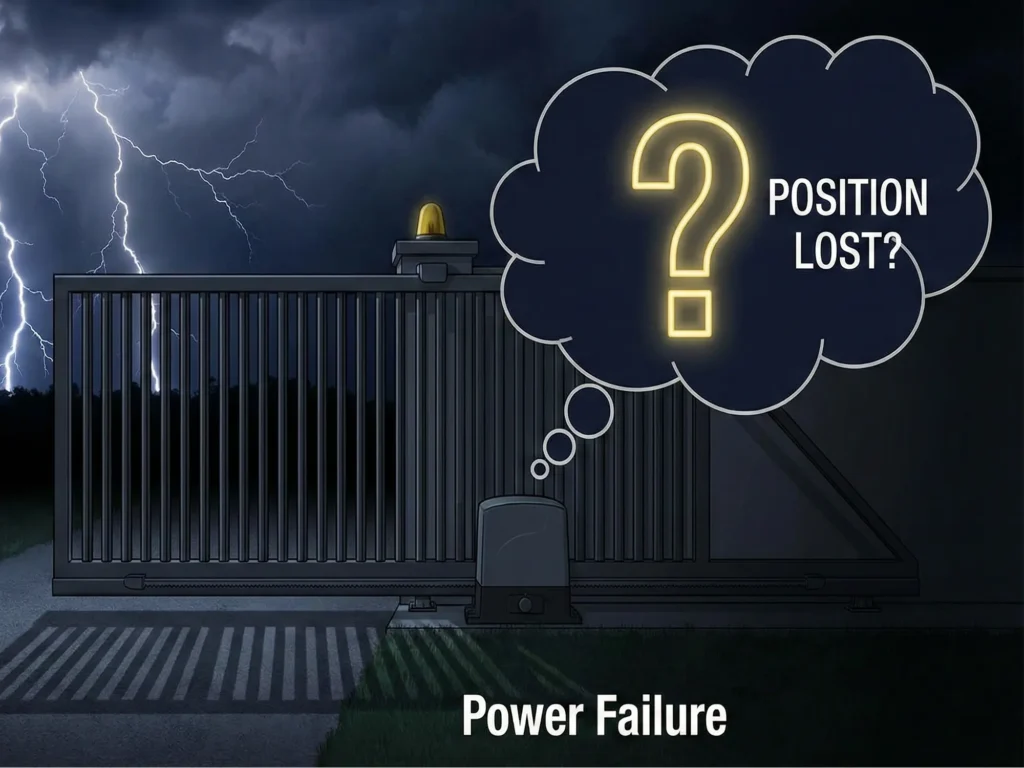

The “Amnesia” Problem (Power Failure)

Most cost-effective gate openers use Incremental Encoders. These sensors count movement splendidly, but they have no concept of absolute position.

- The Scenario: A storm knocks out power while the gate is halfway open. You unlock the manual release clutch and push the gate closed by hand.

- The Consequence: When power returns, the control board’s memory is wiped. It thinks it’s still halfway open. The next time you press the remote, the gate may slam violently into the closing post because its “count” is wrong. (Note: Expensive Absolute Encoders solve this, but their high cost makes them impractical for standard gate openers.)

Mechanical Drift

Over years of operation, gears wear down slightly, and belts might stretch microscopically. The physical reality of the gate begins to drift away from the digital count stored in memory. A gate that stopped perfectly in Year 1 might not close fully in Year 5, requiring a new “learning run.”

The Superior Alternative Emerged

The industry largely shifted to the Hybrid System (internal Hall sensor for speed control + external Magnetic limit for position calibration). This combination solved the “amnesia” problem entirely—every time the magnet passes the sensor, the position is recalibrated, offering the best balance of cost, reliability, and safety.

(See Image 3 below illustrating the power failure issue.)

Conclusion: ACCESS TECH’s Unique Position in 2026

While Encoder-Only limits are now considered a niche requirement, certain unique architectural projects or specific industrial applications still demand them.

Many manufacturers have abandoned this technology entirely. However, ACCESS TECH retains the engineering expertise and manufacturing capability to meet these rare demands.

Whether you need the ultra-reliable mainstream Hybrid System or a specialized Encoder-Only solution for a unique project, in 2026, ACCESS TECH remains your versatile partner in intelligent gate automation.