For any automatic gate system, “moving” is only half the battle. The other half—and perhaps the more critical one—is knowing exactly when and how to stop.

A gate that slams into a post damages the hardware. A gate that stops too early compromises security. To achieve the perfect balance of speed, safety, and precision, modern gate openers rely on a sophisticated “nervous system.”

At the heart of this system lies the Hall Effect Sensor, often working in tandem with Magnetic or Mechanical Limit Switches. In this guide, we break down how these technologies work together to provide a “Double Safeguard” for industrial and residential access.

1. The “Smart” Core: Hall Effect Sensors

In the past, gate openers were “blind”—they moved until they hit a switch. Today, high-end gate openers (especially those with DC or BLDC motors) are “intelligent,” thanks to Hall Effect Technology.

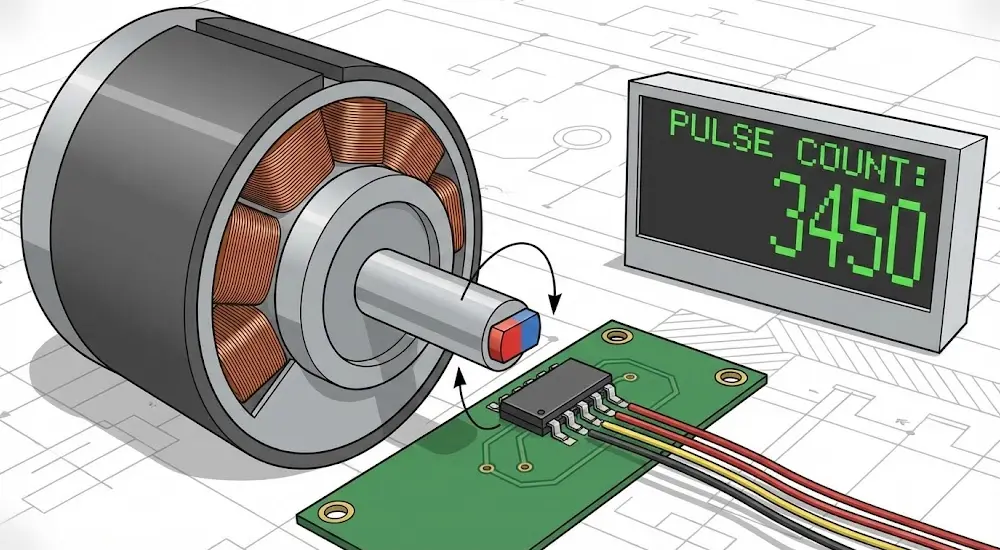

How It Works

Located inside the motor assembly, a Hall Effect Sensor detects changes in a magnetic field. As the motor’s rotor spins, a magnet attached to the shaft passes the sensor, generating a digital pulse signal. The control board counts these pulses to calculate the exact position of the gate.

Think of it as a Pedometer (Step Counter) for your gate. It doesn’t just know the gate is moving; it knows the gate has moved exactly 3,450 pulses.

The Advantages

- Soft Start & Soft Stop: Because the system knows exactly where the gate is (e.g., “90% open”), it can slow the motor down before it reaches the end, ensuring a whisper-quiet stop without mechanical impact.

- Obstacle Detection (Anti-Crush): If the gate hits a car or pedestrian, the motor slows down physically. The Hall Sensor detects this drop in RPM (pulse frequency) instantly and triggers the auto-reverse function. This is faster and safer than traditional current sensing.

2. The “Double Safeguard”: Why We Still Need External Limits

You might ask: “If the Hall Sensor counts pulses, why do many gate openers still have external limit switches?”

This is the principle of Redundancy and Calibration.

While Hall Sensors are precise, they can suffer from “data drift” after a power outage or if the manual release key is used. If the motor is disengaged and the gate is moved by hand, the Hall counter loses its place.

This is where External Limit Switches come in. They act as the “Absolute Reference Point.”

- The Workflow: The Hall Sensor manages the speed and safety during travel. However, once the gate triggers the external limit switch, the system receives a hard “STOP” signal and resets the Hall counter to zero.

- The Result: This “Hybrid Sensing” architecture ensures that even after years of use or power failures, the gate never loses its position accuracy.

3. Comparison: Mechanical vs. Magnetic Limit Switches

When choosing a gate opener that utilizes this external limit technology, you typically have two choices. Which one is better? It depends on your environment.

A. Mechanical Limit Switches (The “Spring Wand”)

Mechanism: Physical contacts inside a box are triggered by a spring wand that hits a stop bracket on the gate rack.

- Pros:

- High Reliability in Interference: Unlike magnetic sensors, mechanical switches are immune to electromagnetic interference (EMI) from nearby power lines or transformers.

- Cost-Effective: Simple, proven technology.

- Cons:

- Wear and Tear: Being a physical mechanism, the spring and internal contacts can wear out over years of high-cycle use.

- Freezing Issues: In extremely cold climates, ice can form on the spring, causing it to stiffen or fail to trigger.

B. Magnetic Limit Switches (The “Reed Switch”)

Mechanism: A sealed glass tube (Reed Switch) containing contacts that snap together when a magnet mounted on the gate passes by.

- Pros:

- Contactless & Weatherproof: No physical touching means no wear. The sensor is fully sealed, making it impervious to rain, dust, and snow.

- Silent Operation: No “clicking” sound when the gate stops.

- Ideal for Harsh Winters: Since there are no moving parts to freeze, it is the preferred choice for cold regions (e.g., Canada, Northern Europe).

- Cons:

- Installation Sensitivity: The gap between the magnet and the sensor must be precise (usually 10-20mm). If the gate rack wobbles too much, the signal might be missed.

Summary: Which One Should You Choose?

| Feature | Mechanical Limit | Magnetic Limit |

| Technology | Physical Contact (Spring) | Non-Contact (Magnet) |

| Durability | Moderate (Mechanical Wear) | High (No Wear) |

| Weather Resistance | Good (Risk of freezing) | Excellent (Sealed) |

| Best Application | Industrial sites with high EMI | Residential, Dusty, or Cold areas |

The ACCESS TECH Solution

At ACCESS TECH, we understand that a gate opener installed in the snowy winters of Russia has different needs than one installed in the heat of Dubai.

As a specialized manufacturer established in 1999 with over 285 patents, we offer a diverse range of gate automation solutions:

- Smart Core: Most of our modern DC gate openers utilize Hall Effect Technology for superior safety and soft-stop features.

- Customizable Limits: We provide both Mechanical and Magnetic limit options depending on your market’s requirements. Whether you need the rugged simplicity of mechanical switches or the weatherproof reliability of magnetic sensors, we have the engineering capability to deliver.

Looking for the right technical specification for your market?

Visit at-gateopener.com or at-barriergate.com to explore our full range of intelligent gate operators.

ACCESS TECH – Secure Access, Reliable Tech.