In the world of perimeter security, a “cheap” motor often becomes the most expensive one due to constant part replacements and technician visits. To ensure a “fit-and-forget” installation, professional contractors should evaluate motors based on the following technical pillars.

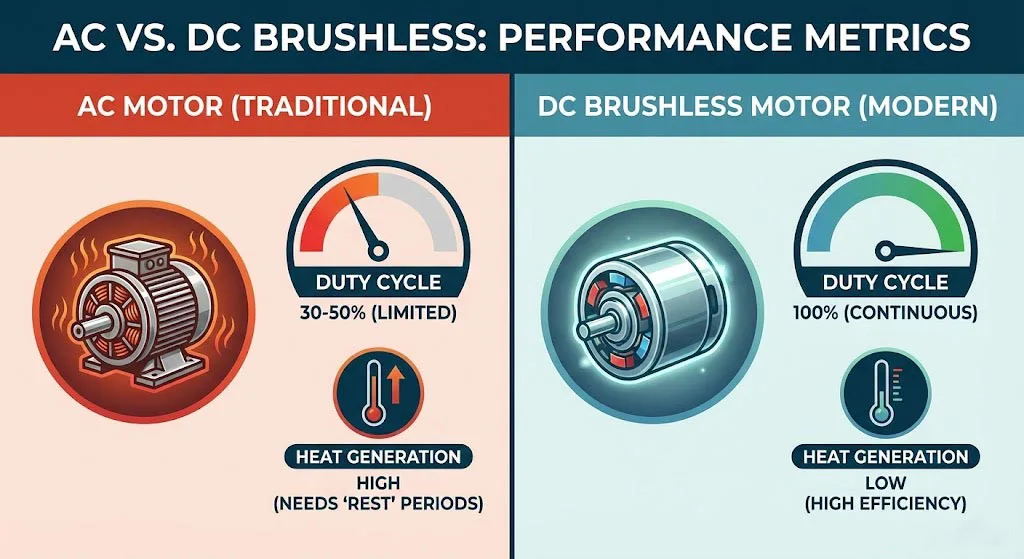

1. Prioritize DC Motors over AC

While AC motors are traditional workhorses, DC (Direct Current) sliding gate motors are the superior choice for modern, low-maintenance applications.

- Reduced Heat Build-up: DC motors run significantly cooler than AC motors, especially during high-frequency use. Overheating is the primary killer of motor insulation and control boards.

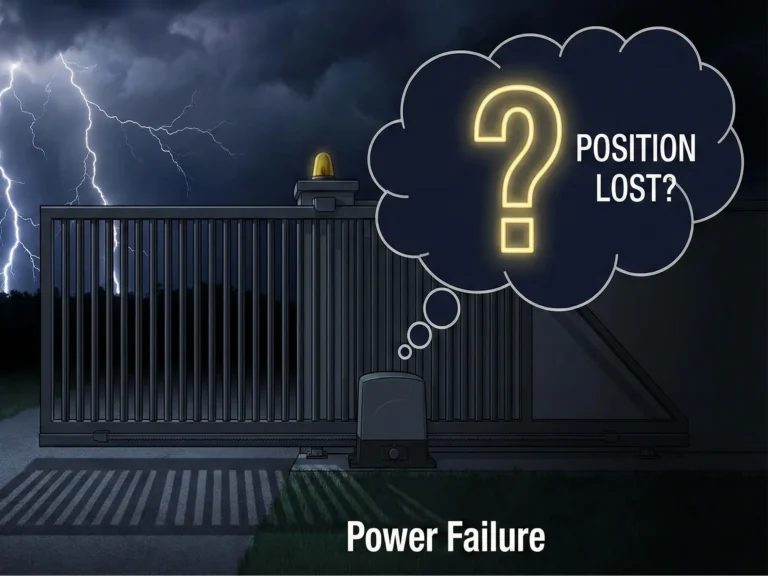

- Battery Backup Integration: DC systems natively support battery backups. This reduces maintenance calls during power outages, as the gate remains operational without the client needing to use the manual release key.

- Precise Control: DC motors allow for much finer adjustment of speed and force, preventing mechanical strain.

2. Demand “Soft Start” and “Soft Stop” Functions

Mechanical wear and tear is the leading cause of gate failure. A motor that slams the gate into the physical stops will eventually shake itself to pieces, loosening the rack and damaging the gearbox.

- The Mechanism: These functions allow the gate to accelerate gradually at the start and slow down before reaching the limit switch.

- The Benefit: It eliminates the “jerk” and “impact” forces. For a contractor, this means fewer calls regarding misaligned racks, broken limit switches, or noisy operation.

3. Verify Compliance with Rigorous Safety Standards

A low-maintenance motor must be a safe and legally compliant motor. Never accept a supplier’s word without seeing official CE Certification. Look for compliance with these specific standards:

- EN 60204-1:2018: This covers the Safety of Machinery, specifically the electrical equipment. It ensures the control system is robust against electrical faults and environmental interference.

- EN 60335-1: This focuses on the Safety of Household and Similar Electrical Appliances. It guarantees that the motor is built to prevent shocks, fires, or mechanical hazards under normal and abnormal operations.

- EN 61000-6-1/3 (EMC): Electromagnetic Compatibility. This ensures that the motor’s high-power start-up doesn’t trip your client’s Wi-Fi or smart home sensors, a common “hidden” maintenance headache for contractors.

- EN 12453: This is the core standard for “Safety in use of power-operated doors.” It defines the requirements for anti-crush force limits. A motor compliant with this standard has been tested to ensure that if it hits an obstacle, the impact force is within safe limits to prevent serious injury.

- EN 12445: This specifies the test methods used to verify EN 12453. It ensures that the “Auto-Reverse” function isn’t just a marketing claim but a laboratory-verified safety feature.

4. The “Hidden” Low-Maintenance Factors

Beyond the motor type and software, these physical attributes determine how often you’ll need to return to the site:

A. Magnetic vs. Mechanical Limit Switches

Mechanical switches rely on a physical spring that can rust or snap. Magnetic limit switches (like those found in the ACCESS TECH C-Slider series) have no moving parts and are unaffected by dust, ice, or rain, making them virtually maintenance-free.

B. Gearbox Lubrication & Materials

- Die-cast Aluminum Housing: Protects internal components from corrosion.

- Permanent Lubrication: High-quality motors use synthetic grease or oil baths that are sealed for life, eliminating the need for periodic greasing.

C. IP Rating (Ingress Protection)

For outdoor gate openers, an IP54 rating or higher is non-negotiable. This prevents dust and water splashes from entering the housing and causing short circuits on the control board.

D. Smart Diagnostics

Look for boards with an LED or Digital Display that shows error codes. If a maintenance issue does arise, the client can read the code to you over the phone, allowing you to bring the correct part on the first trip, rather than making two separate visits.

Conclusion

For the savvy contractor, the goal is to provide a solution that “just works.” By selecting a DC-powered motor with Soft Start/Stop and verified EN certifications, you eliminate 80% of the common failure points in gate automation.